lot traceability system

Ad Intelligente Produktentwicklung mit SAP Enterprice Product Developement. A User can determine what can be purchased or sold by Lot status.

Inventory Traceability Manufacturing Erp And Traceability Software

Matrix Controls provide ERP Integration Services.

. Once ingredients components lot information is entered into the traceability software all authorized employees can access it. This is because a modern WMS uses new technology to track the movement and storage of materials and finished goods creating real-time information about materials. A warehouse management system WMS makes it much easier to gain traceability throughout your warehouse.

In turn manufacturers will achieve high-level companywide traceability to ultimately reduce time valuable resources and the costs incurred by defective. Our opinions are our own and are not influenced by payments from advertisers. Ad Seamless integration with popular eCommerce sales channels accounting tools.

By scanning QR code label on the shop floor and via the web interface in the office. Track stock lots and batches of products. In addition to MES ERP and Professional Services.

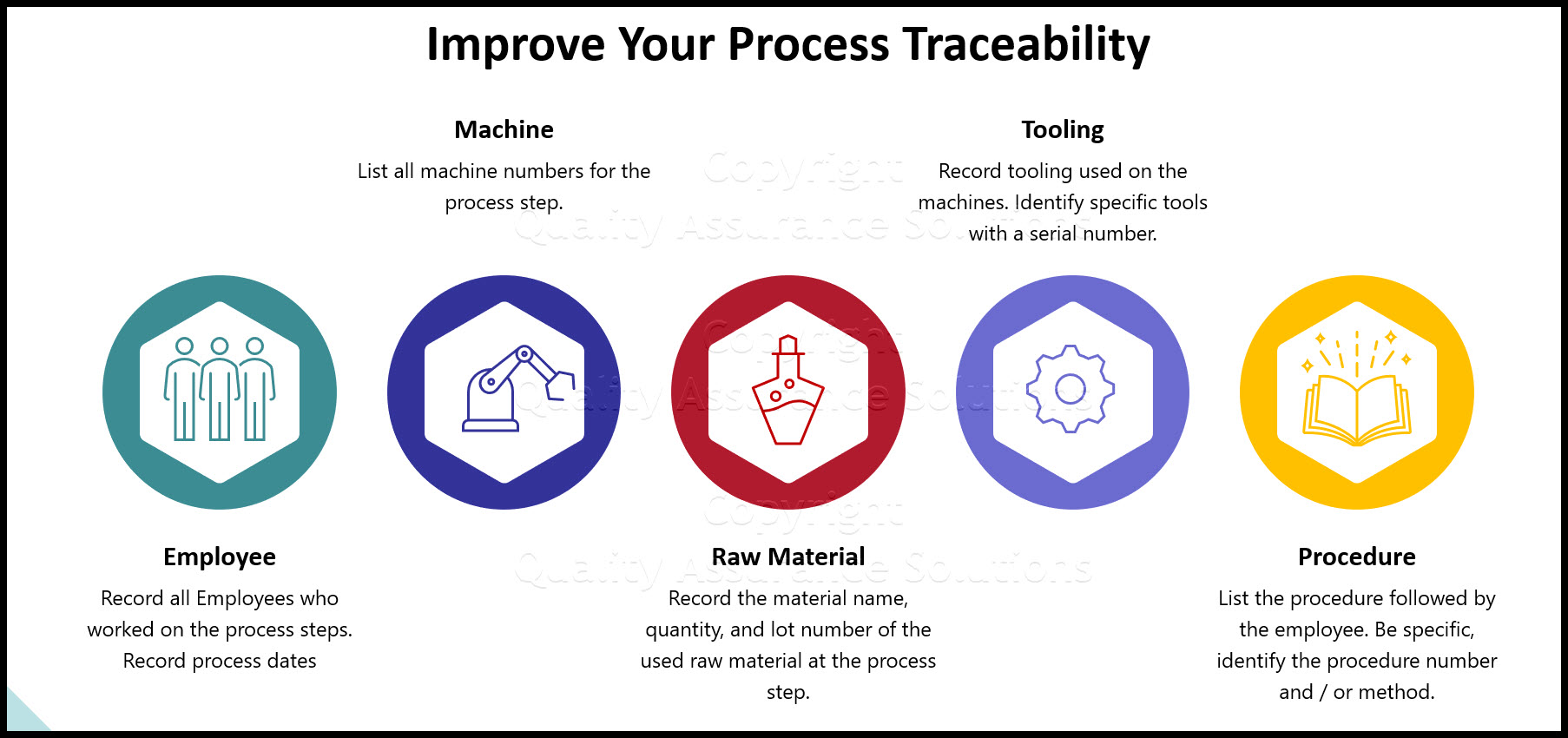

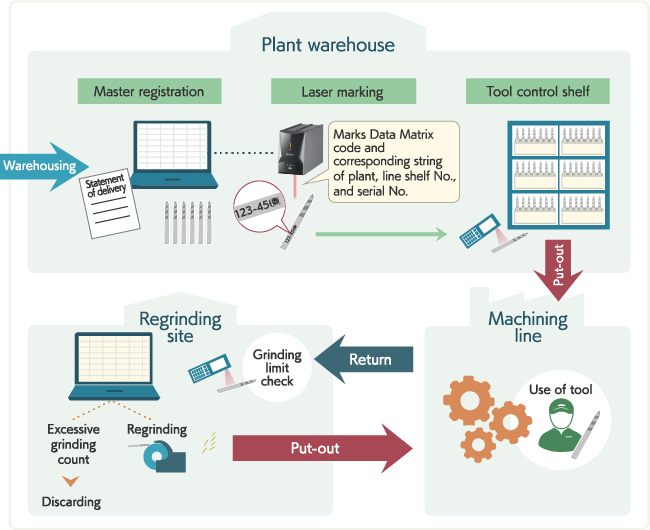

Organize product returns and callbacks. Increasingly were seeing manufacturers invest in machine vision systems to keep better track of parts as they move through the assembly line. For traceability in manufacturing processes each product or lot is assigned an identification number and then information such as work details inspection results and dimensions are linked to this identification number in each process so that it can be utilized for assembly in a later process.

Nutzen Sie das Innovationspotential und fördern Sie die Transparenz in Ihrem Unternehmen. Which materials and how much were used in the creation of a given batch of goods. We publish unbiased reviews.

Utilizing the First In First Out FIFO or the First Expired First Out FEFO method along with lot tracking ensures that inventory waste is kept at a minimum. The benefits of Lot Traceability Tracks the part from receipt of materials into production and through to product delivery and inventory transaction records lotserial information Track which lot controlled items were used to produce specific finished products in manufacturing process. After tracking events in the supply market context seeing immutability as a fundamental rule of product handlers the company chose private blockchains and needed authorization.

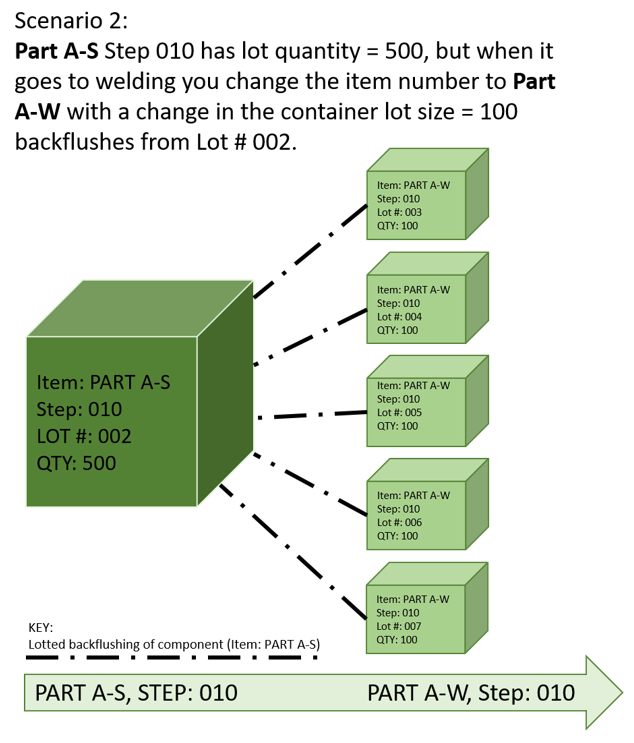

Lot tracking and traceability helps you more accurately track whats going on in your business and unlock the full potential of your ERP software. Many of the companys customers are requesting full lot traceability. AIM Computer Solutions developed an alternate ERP-based solution for lot control for Metro-Detroit automotive supplier Warren Screw Products Inc.

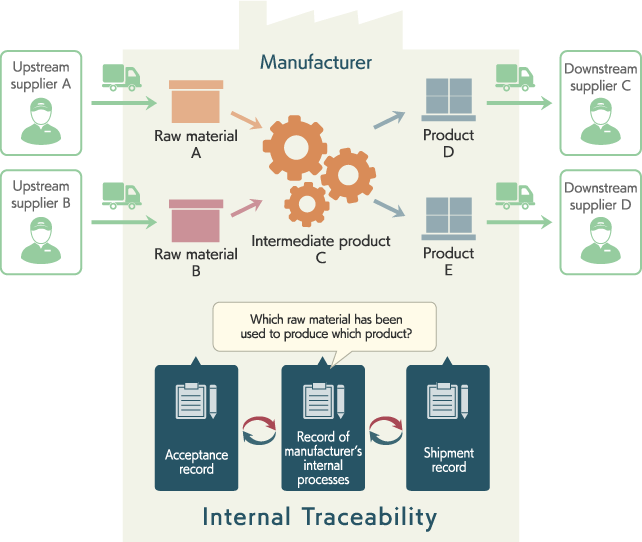

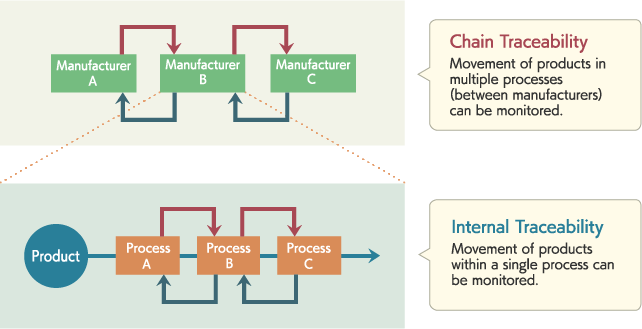

The system ensures each weighed ingredient has enforced - tolerances preventing recipe completion until all ingredients are weighed using the green the target zone. Two types of lot traceability can be employed. Track inventory movements and expiry dates.

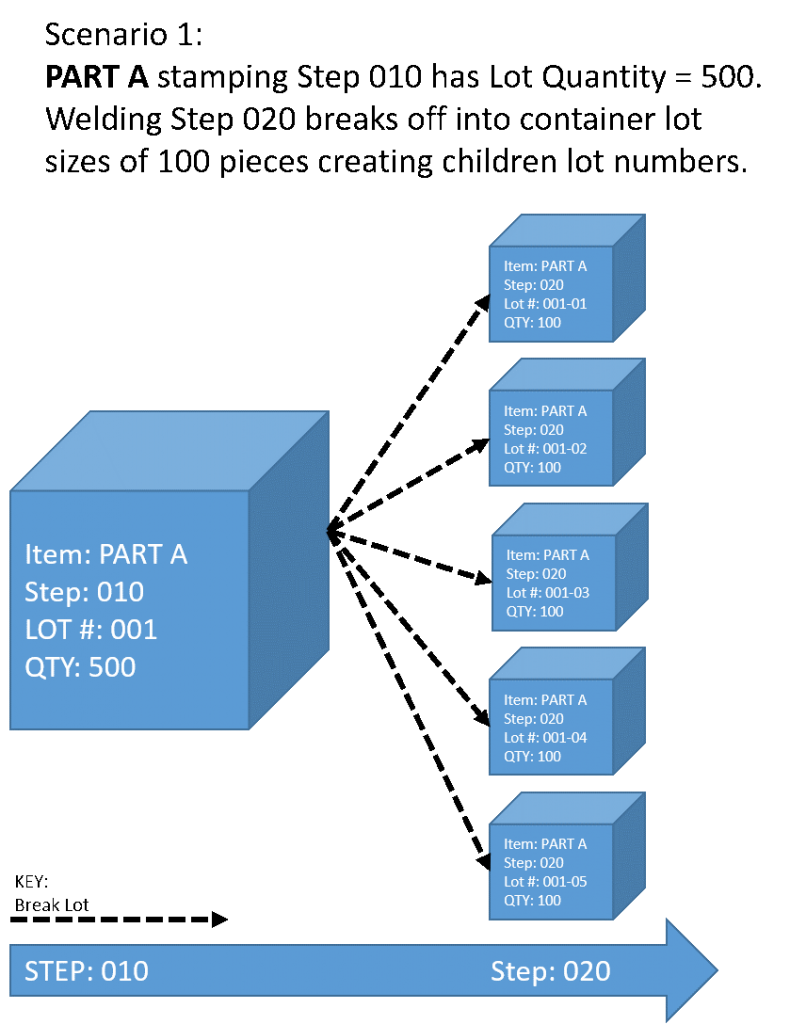

Easily find the source of product non-conformance. Optimal detailed lot traceability incorporates multi-level track and trace for maximum visibility for example by batch lot serial number etc as well as in combinations of these. A Lot tracking system is a system that records information associated with a batch of product.

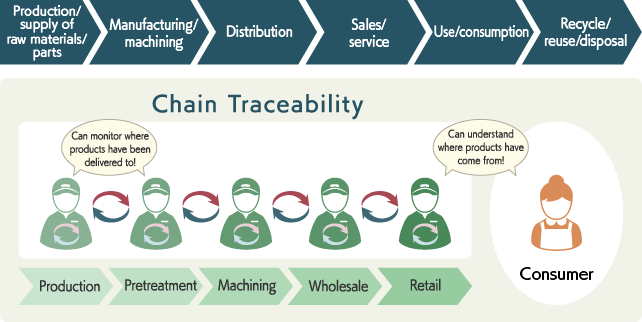

Manage product planning activities and ensure on-time purchasing of materials. In food processing software traceability systems imply the use of a unique piece of data eg order datetime or a serialized sequence number generally through the use of a barcode RFID which can be traced through the entire production flow linking all sections of the business including suppliers future sales through the supply chain. Warren Screw Products Inc.

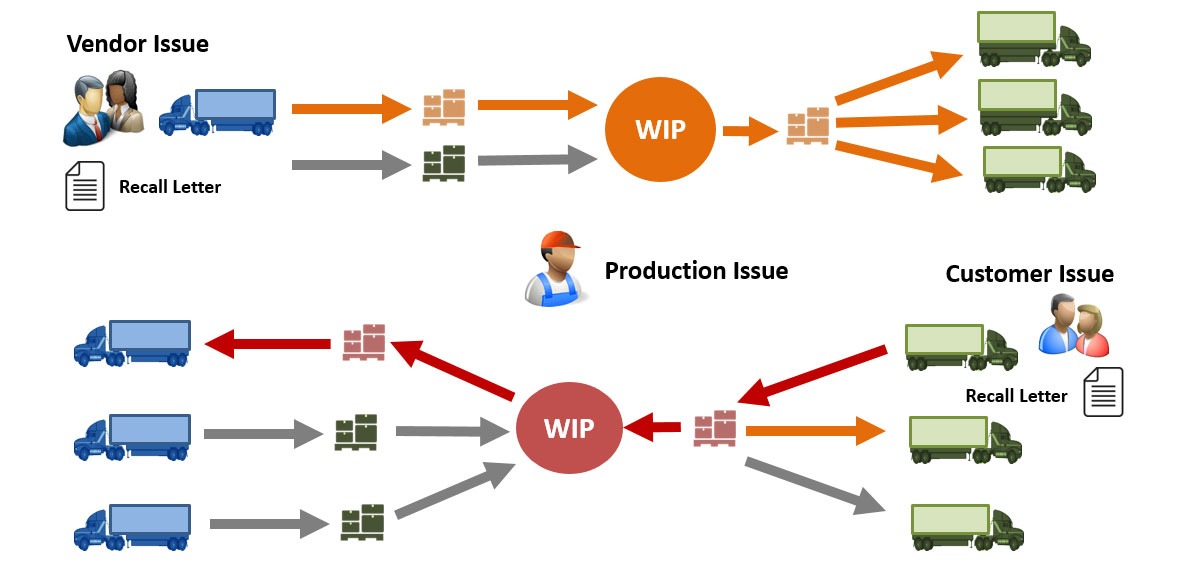

With a lot traceability system you have a way to track problem goods from the customer all the way back to the supplier who sent the raw materials and all the. Lot traceability also called lot tracking lot control or manufacturing traceability means that you know which supplier lots were used in which finished products and who received those finished products. Using this information for machining contributes to the improvement of.

No more lost time wandering through warehouses wondering where you put an item or ingredient. This content is reader-supported which means if you leave your details with us we may earn a commission. The supplier you purchased from and date in which the items were purchased is also recorded allowing you to track an individual group of products or shipment from your supplier.

Ad Seamless integration with popular eCommerce sales channels accounting tools. TOP 18 Lot Traceability Software. Lot tracking gives you a snapshot of your entire.

Nutzen Sie das Innovationspotential und fördern Sie die Transparenz in Ihrem Unternehmen. It could be as simple as knowing what raw material went into a particular batch of product. Industry-built to support your quality and safety systems SYSPROs Lot Traceability module offers a full traceability system helping you improve governance and drive compliance to minimize the effects of a recall.

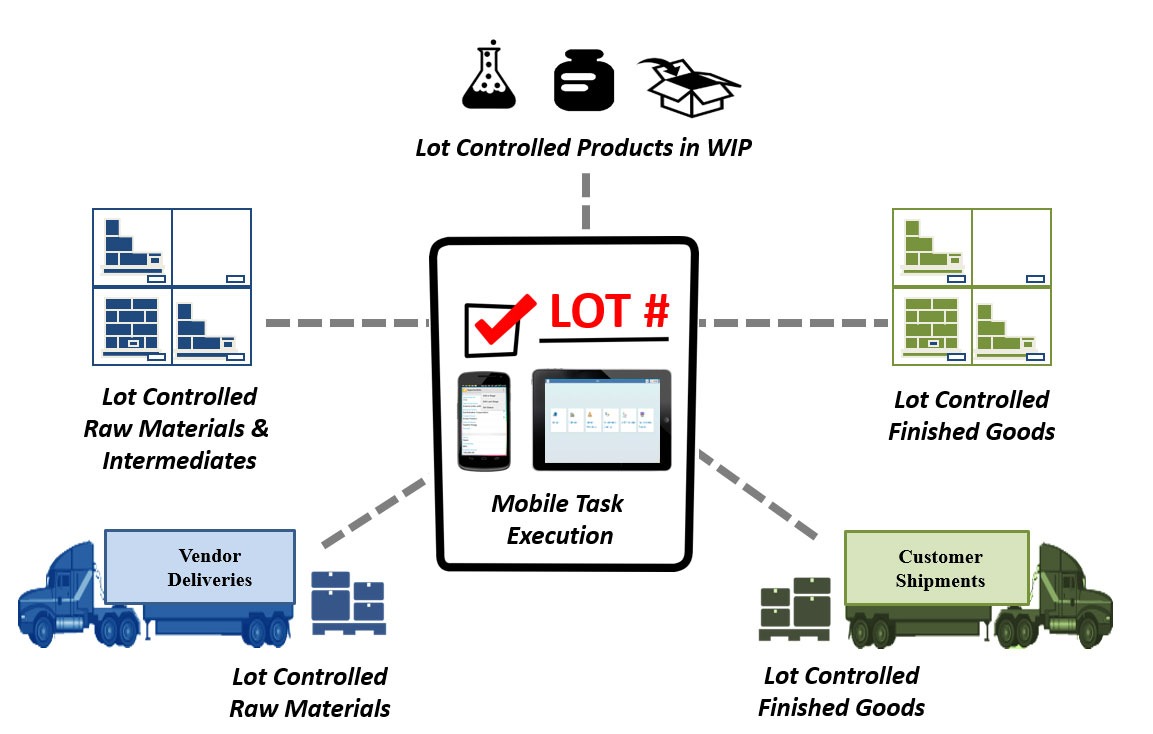

Good lot traceability is bi-directional that is the lots path can be traced both upstream to its components and manufacturing process and downstream to customers and distributors. It caters for the tracking of materials through receipt manufacture assembly inspection stocking and final distribution while maintaining quality. Manage product planning activities and ensure on-time purchasing of materials.

Authorized shop floor employees can update lot batch information add new data obtained during the production process and add images taken with a smartphone. Lot tracking or batch tracking helps your business with product traceability to keep track of which of your customers received specific groups or shipments of items and when they were received. Lot traceability also known as Lot control or manufacturing traceability means a system which has the comprehensive functionality to track problems and provide full visibility of the exact make-up of consumer goods in real-time throughout its manufacturing process.

The modular nature of the SYSPRO ERP software provides scalability and flexibility and allows you to select only those functions needed to increase operational control and efficiency across the entire supply chain. Data Capture Mobility Hardware Mobile computers bar code. Industry-built to support your quality and safety systems SYSPROs Lot Traceability module offers a full traceability system helping you improve governance and drive compliance to minimize the effects of a recall.

Benefits of lot tracking and traceability. Expiry dates and user defined. In the video below we show you how this works using WiSys WMS for Macola.

Lot tracking allows companies in industries that deal with perishable goods to keep an eye on the expiration dates of their materials or products. The major conceptual points of a robust lot traceability system include. In traceability solutions system capabilities may include serialized container and individual part tracking.

Current Lot traceability system solutions are costly or imperfect and give rise to problems related to the organization and trust. Provenance a UKs start-up is one of the. Ad Intelligente Produktentwicklung mit SAP Enterprice Product Developement.

And detailed traceability from any point in the manufacturing process. Is a manufacturer of turned broached machined and assembled metal components for automotive OEMs. A graphical lot traceability tool executes bi-directional searches to pinpoint on hold inventory vendor deliveries and customer shipments.

An easily searchable database of lot traceability provides fast analysis for correlation and replaces the burden of manual engineering trial and error. Some of the key benefits include. BatchMasters lot traceability software can help food manufacturers exceed product traceability and recall code requirements stipulated in BRC SQF advanced food safety certification programs.

Lot tracking allows you to track several units of a stock item using the same lot or batch no. Built-in bar code printing and scanning RFID and direct part marking. Lot traceability is an essential tool for any and all production processes and a dedicated manufacturing ERP software will ensure timely accurate and reliable inventory and production workflows and reporting.

Lot traceability is the act of tracking and documenting a lot batch or group of goods that were made during the same manufacturing run using the same raw materials components and parts. Start a free trial. The systems scans and validates lot numbers providing real time inventory usage and eliminating costly traceability paperwork.

It caters for the tracking of materials through receipt manufacture assembly inspection stocking and final distribution while maintaining quality. Lot Tracking and Traceability Software for SMEs MRPeasy helps ensure end-to-end traceability in your supply chain.

Traceability Lot Control And Quality Assurance Aim Computer Solutions

Importance Of Lot Number Lot Number Tracking Capabilities

What Is Traceability Verifarma

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

Why Traceability Matters In Manufacturing Youtube

Traceability Of Material When It Comes To Lot Traceability We Ve Got Your Back Digi

Lot Traceability And Recall Management System

Structure Of A Food Traceability System Download Scientific Diagram

Detail Of Process Flow For Food Product Traceability 17 Download Scientific Diagram

What Is Traceability Traceability Solutions Keyence America

Traceability In The Production Process Technical Article Macsa Id

What Is Traceability Traceability Solutions Keyence America

Product Information Traceability System

Basics Of Lot Traceability Recall Containment Youtube

Lot Traceability And Recall Management System

![]()

Lot Traceability Software For Process Manufacturing

What Is Traceability Traceability Solutions Keyence America

What Is Traceability Traceability Solutions Keyence America

Traceability Lot Control And Quality Assurance Aim Computer Solutions

0 Response to "lot traceability system"

Post a Comment